- Manufacturing and exporting Hex bolt and Nut

- Manufacturing and exporting Stud bolts and Nuts

- Manufacturing and exporting Sucket (Allen) bolts and Nuts

| HOME |

| ABOUT US |

| PRODUCTS |

| Hex Bolt |

| Sucket Bolt , Allen Bolt |

| Stud bolt |

| Hex Nuts and Heavy Hex Nuts |

| Washer |

| GALLERY |

| CONTACT |

There are different ways to fasten two sections of one component or machine to each other in different industries such as Welding, Bolt and Nut, Glue, Nail and … Metal industry is by far the most comprehensive industry of all and this industry is undoubtedly heavily dependent on Bolt and nut as the fastening component. There are both advantages and disadvantages to use bolt and nut as fastener, but what has made them the most common fastener is their flexibility and periodic replacement option. Bolts and nuts and other fastening machines driven from them like stud bolt are vastly used in Gas, Oil and petrochemical, Construction, Machinery, and, etc. Other shapes of bolts, also known as screws, are used commonly in other industries as fasteners.

Ajax bolt and nut Co. is an Iranian Manufacturer of Hex Bolt and Nut , Sucket Bolt and Stud Bolts. These Products are manufatured following the international standards of DIN, ISO and ASTM.

Bolts and nuts are made of different materials based on their application and the environment they are used in. these materials vary from low carbon alloy class 4.6 and 5.6, average carbon alloy class 8.8 and high carbon class 10.9 and 12.9. Other materials such as stainless steel 304 and 316 and titanium are also used to manufacture bolts and nuts. The mentioned classes and grades in American standard system which are 2, 5 and 8 are the most important factor to determine the tensile, resistance, sheering stress, tension and the physical strength of bolts and nuts. The higher these numbers, the stronger and yet crunchier the bolts and nuts are.

Coating metals has always been a good way to protect it from humidity and corrosive substances. Depending on the sensitivity of metal, density of humidity and corrosive substances, type of corrosive material either it is acid or omnium different ways of coating are being used. Zinc coating and cadmium coating are the most common ones for bolts and nuts. The bolts and nuts and the stud bolts that are being used in Oil and gas industry require stronger coating that sewage industry therefore the former is usually cadmium coated and the latter is zinc coated.

Hot deep Galv, Cold Galv and Dacromet galvanization are mostly used for bolts and nuts. Each of them has pros and cons. However, Dacromet galvanization is the most modern and effective way with the least trouble to assemble and maintain the end products. Dacromet coating process takes place in 260 degrees centigrade which is much lower than the temperature used for hot deep galvanization. At this temperature the grade of bolts and nuts are maintained properly and the end product suffers no extra volume.

There are many different factors that should be considered thoroughly to choose the right diameter, length, material, manufacturing standard, thread type, head type and coating of bolts and nuts. Therefore, choosing the right bolt and nut is completely a technical process requiring both mechanical knowledge and experience. Among the choosing factors application, load and environment are the most effective ones.

Application of bolt and nut is the most important factor to choose the right type of bolt and nut. For example, hex bolt and socket bolt are widely used in construction and machinery. Stud bolts are commonly used in oil and gas industry , …

The loading determines the tension and sheering stress applied on the component and therefore it is the most important factor to choose the right material, manufacturing standard and the size of bolt and nut.

The invironment, whether it is dry or humid, cold or hot, pure or with density of acid or ammonium, is an important factor to choose thematerial and the coating of bolts and nuts.

Hex Bolt

Hex Bolt

Ajax bolt and nut co is a manufacturer of full treaded hex bolts DIN 933, partially treaded hex bolts DIN 931 with different classes, grades and standards for different industries including construction, dam and bridge construction, oil, gas and petrochemical, sewage industry , etc.

Socket bolt

Socket bolt

Ajax bolt co is manufacturer of socket bolts for machinery industry full and half threaded following the standard DIN 912. our hex bolts are made of high and low carbon alloy steel, stainless steel and titanium depending on your request and floowing classes of 5.6, 8.8, 10.9 and 12.9

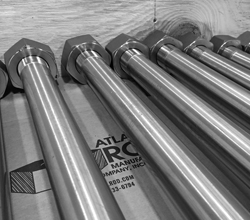

Stud bolt

Stud bolt

Ajax bolt co is one of the leading manufacturers of stud bolt with heavy nuts in Iran. Our stud bolts are manufactured using B7, B8and B16 rods and following the international standard of ASTM A 193 highly used in oil, gas and petrochemical industry and vessels.

Hex Nuts

Hex Nuts

Our nuts are manufactured of high carbon and low carbon alloy steel following DIN 934 for hex and socket bolts and ASTM A194 for stud bolts. Class and grade of nuts are also mentioned by a digit 5, 8,10 and 12 on the edge. it's recommended to use nuts with equal class of bolts.

ASTM International is an american organization introducing technical standards based on american engineering society established in 1898. This standard organization has introduced a wide range of catagories for bolts, nuts and stud bolts. the most well known ASTM standards are A320, A490, A193, A307 , ... that are

ASTM International is an american organization introducing technical standards based on american engineering society established in 1898. This standard organization has introduced a wide range of catagories for bolts, nuts and stud bolts. the most well known ASTM standards are A320, A490, A193, A307 , ... that are

DIN (Deutsches Institut für Normung) is the mechanical standard organization of Germany as the mother of industry. this standard has designated various sections for bolts and nuts defining head type, thread type and thread length of bolt and nut. most well known DIN standards for bolt and nut are 931, 933, 934 and 912.

DIN (Deutsches Institut für Normung) is the mechanical standard organization of Germany as the mother of industry. this standard has designated various sections for bolts and nuts defining head type, thread type and thread length of bolt and nut. most well known DIN standards for bolt and nut are 931, 933, 934 and 912.