- Manufacturing and exporting Hex bolt and Nut

- Manufacturing and exporting Stud bolts and Nuts

- Manufacturing and exporting Sucket (Allen) bolts and Nuts

| HOME |

| ABOUT US |

| PRODUCTS |

| Hex Bolt |

| Sucket Bolt , Allen Bolt |

| Stud bolt |

| Hex Nuts and Heavy Hex Nuts |

| Washer |

| GALLERY |

| CONTACT |

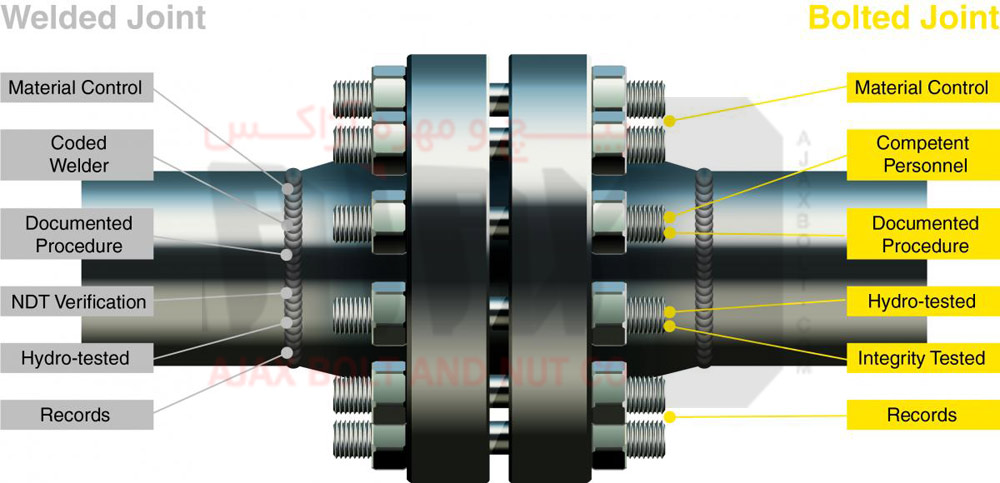

One of the most exciting and yet controversial discussions in industry is the competition between bolt and nut joints against welded joints. Choosing one of the two is closely dependent on different factors. Right now, Welding is dominant in United States of America and many other American countries. While, many European countries including Germany as the mother of industry are more reliant on bolt and nut connections.

The joint type choosing factors include Cost, Safety, Material and the most important of all the mother industry the joint is used in, since different industries require different standards under various pressures and various temperatures. Below are some of the advantages and disadvantages of each method.

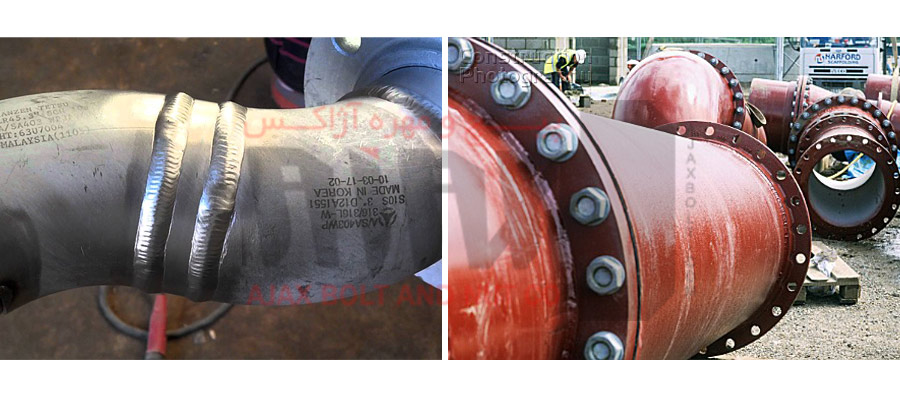

A welded joint can provide equal strength as the parts of joint had been originally assembled as one united piece. This is if the welding process is done accurately and by a coded, well experienced welder.That is why, there are different test certifications required for welded joints, since the quality, strength and safety of welded joints are very much dependent on welding process itself.

One of the other advantages of welded joints compared to bolted joints is their reliable performance under dynamic loads and vibration. Bolted joints are always facing loosening phenomenon under dynamic loads and require locking mechanism.

Welded joints are followed by hydro test, gas test and other integrity tests and therefore are more traceable and more accurate. Bolt and nuts also have hardness test, Charpy test, …. However, these tests are conducted before connection on the machinery itself and not on the joint.

Bolt and nut connections may not serve the same strength of the parts manufactured as one united piece like well welded joints, but since the bolting process is more routine and requires less qualification, bolted connections provide acceptable strength , durability and safety, something that can be hardly said about welded connections unless due inspections are performed. Note that lower strength in bolted joints is due to the drill holes in the surface to pass the bolts through and the very narrow gap remaining between clamping sections.

Welding happens in very high temperature which will harm the metal plating and lessen the hardness of metals. Furthermore, Welding can be very challenging when the connecting sections have different material and are of different sizes.

The connecting sections are involved directly in welding process and any inaccuracy can harm them in a way that the connecting parts themselves need to be replaced. Bolt and nut connections, however, do not involve the connecting sections and are easily replaceable.

Welding process can take a long time especially if depth inspection is required. Furthermore, the coded welders charge a lot of money and in many industries finding a well experienced coded welder is hard.

All in all, if you are not running a very expensive high tech project, bolt and not connection is your answer since it provides acceptable safety and durability. The expenses of a professional welding and the following inspections can be very high. Bolt and nut